Wood Flooring FAQs

Browse through some commonly asked questions related to flooring.

The type of wood cut is determined by the angle at which a board is cut from the log.

There are four commonly used cuts of wood: Plain sawn, Quarter sawn, Live sawn and Rift Sawn. Each of these cuts produces a plank of different appearance. Lets lake a look..

Plain Sawn: The most commonly used cut is plain sawn. The log is squared and sawed lengthwise by parallel cuts. The growth rings appear as straight lines on the board, joining at the end to form a parabola. Because of this appearance, plain sawn boards are often considered the most appealing of the cuts. These planks are ideal for floors, tables or furniture. Plain sawn planks are usually the least expensive planks as their production leaves very little waste.

Quarter Sawn: Quarter sawn planks are produced by cutting a log into quarters and then making parallel cuts, perpendicular to the tree’s growth rings. The grain in quarter sawn wood is more consistent and the growth rings will be at a 60 to 90 degree angle in the plank. This method makes quarter sawn boards less likely to cup, warp or twist.

Rift Sawn: In this cutting method the log is quartered and then cut. As the cuts get closer to the outside of the log the angle of the grain changes to 30-60 degrees. This cut makes an easy to match board for a uniform appearance of your surface.

Live sawn: Live Sawing is straight cutting the log from the outside diameter through the heartwood. The boards incorporate the full range of the log’s characteristics resulting in a unique mix of clear and natural grades with grain direction varying from plain sawn to rift & quartered sawn.

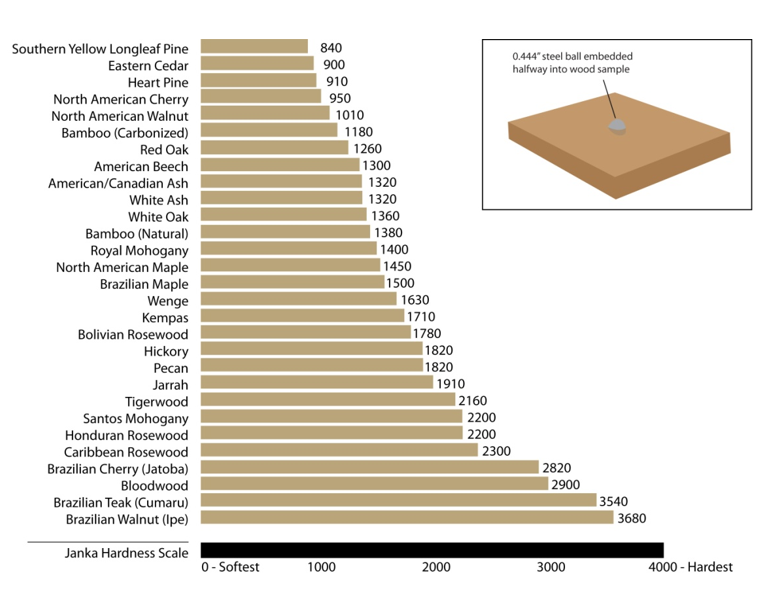

The Janka wood hardness test measures the resistance of a wood sample to denting and wear.

Specifically, the Janka scale measures the force required to embed an 11.2 millimeter (0.444 inch) diameter ball halfway into a wood sample. A common use of Janka hardness rating is to determine whether a species is suitable for use as wood flooring.

Mission Hardwood Floor Co. can craft a floor for you from almost any wood species. See how it will hold up on the Janka scale.

PROPER MAINTENANCE WILL MAKE YOUR FLOOR LAST A LIFETIME OR LONGER!

LIGHT CLEAN:

Giving your hardwood floors a good dusting with a microfiber mop or cloth works great for a quick clean. Using a broom is effective as well.

THOROUGH CLEAN:

Using a vacuum with a brush head is perfect for your hardwood floor. You can also lightly mist your floor with a hardwood floor cleaner and use a mop to give the hardwood a great clean. A gentle touch is one of the best ways to clean your hardwood floor.

POLISH YOUR FLOOR:

Polishing your hardwood floor every few months is a great way to renew and refresh the finish. Polishing your floors fills in the microscopic scratches and evens out your floor’s protective surface.

DEEP CLEAN:

Consider giving your floor a deep clean or a sand and refinish every three to five years. Sanding and refinishing your hardwood floor completely removes the old protective finish and replaces it. If your floor has some deep scratches or gouges, sanding and refinishing can repair this damage, leaving you with immaculate hardwood flooring that looks like it did the day it was crafted.

Here’s an informative video and an excellent product on hardwood floor care: